As a builder or concreter, concrete slab defects are definitely something you want to avoid if possible. They can delay payment for work on which you’ve already paid for materials and labour, and also delay further progress on the project, taking up large slabs of your time, costing even more money. But when the unexpected strikes, you want to receive a certified slab defect rectification ASAP, and get back on track.

That’s why we’ve made system changes to the ordering and design of slab defect rectifications. We’ll have more on that, and how builders can speed things along too, but first let’s cover some basics.

A millimetre perfect construction project is a rare thing indeed. But how far out can something be before it is regarded as a “slab defect”? All work must comply with the National Construction Code (NCC) and state authorities (for example Queensland Building and Construction Commission) issue regulations describing the standards and tolerances allowable for all aspects of construction.

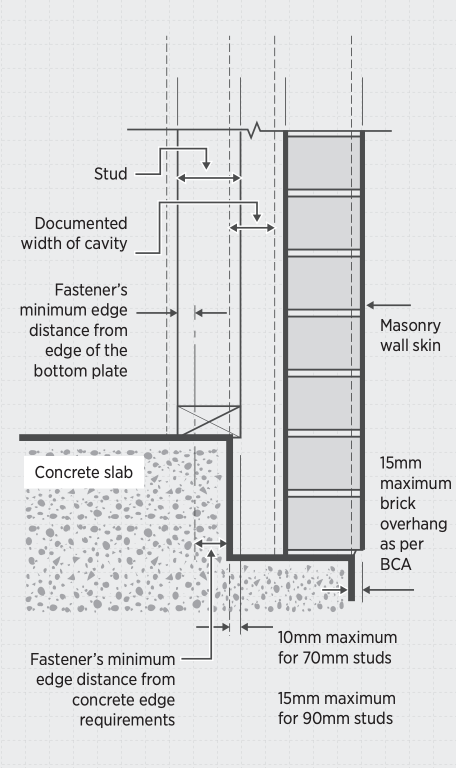

For example, Diagram 1 below shows a brick overhang less than 15mm over the slab edge is not considered to be a slab defect in Queensland. This also applies in New South Wales, however the limits applied are 10 mm for a 90 mm frame and no overhang allowance for a 70 mm frame. QLD is more lenient with 10 mm for a 70 mm frame and 15 mm for a 90 mm frame.

There is a range of areas where slab defects can occur with concrete slabs, including:

This blog deals with slab defects requiring engineering assessment and/or intervention (largely within the area of Dimensions). They include:

The sooner a slab defect is detected the better, but that’s easier said than done. There are two main factors involved:

The most common times a slab defect is discovered are when the:

But time is of the essence, so what happens once a slab defect is detected?

No matter how and when the slab defect is detected, there’s a lot to be done:

Could there be a faster way of doing this?

Slab defects vary greatly in:

Where repairs have been attempted, they vary in:

Engineers assess all these factors before quoting on the job and delivering a rectification design. The builder then completes the work and books an inspection.

It’s clear that slab defect rectification can be complicated, so it takes time. But you want to minimise delay in certification of the frame stage, because without that you can’t:

There are three main issues in the efficiency of the defect rectification process:

The first two are problems at the builder’s end. But there’s no point just pushing on in the hope that it will just work itself out. And though wanting to avoid delay, many builders who try a quick fix to slab defects end up realising their solution isn’t sufficient, or they’ve used the wrong product. Trying a DIY fix on slab defects and then asking an engineer to certify your work is not the way to go.

Both of these approaches ultimately affect the third issue, as the engineer has to work with more complexity that could have been avoided. In some cases, the engineer simply cannot certify the builder’s rectification attempt, and the expenses become much more significant. No one wants to pull down a brick wall and steel frame or wall cladding to fix a defect and then begin all over again, but that’s what can happen without early detection or advice to the engineer that there may be a problem.

The third issue sits with engineers. Many minor defect problems still go through the normal extensive internal project design and checking channels of an engineering firm, which we listed in the section above. This can be a cumbersome process for small jobs, causing delay and frustration. Additionally, builder reluctance and DIY rectification work can mean too much back-and-forth before getting to all the facts (rectification attempts, products used, installation method etc) and solving the problem.

To fix this, STA has improved its systems, streamlined processes and now provides faster solutions (with help from clients). Here’s how it works.

The diagram earlier in this blog showed the QBCC tolerances for frame bottom plate overhang. Within this range, there is demonstrably “no defect”, and a rectification is not required. By better educating our clients about when not to worry, we plan to save time for everyone.

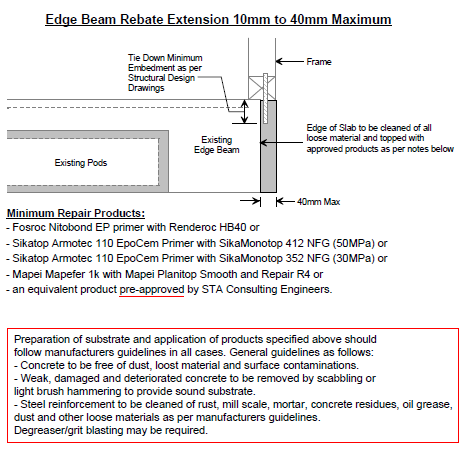

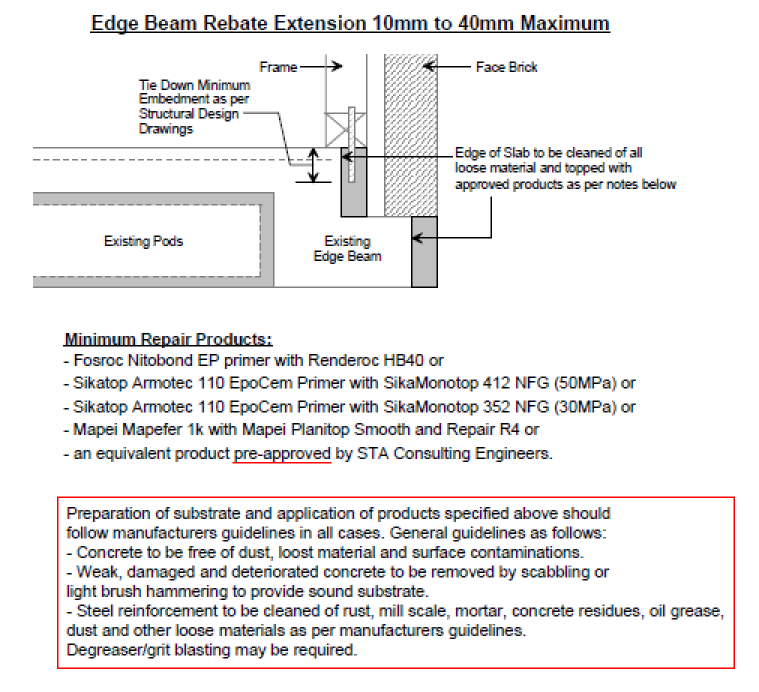

Outside the tolerances, STA has analysed thousands of slab defect rectifications, and developed standard engineering details to rectify most minor issues. We can now offer standard rectification details that regular customers can keep on file; for example, an engineering detail for rectification of frame overhang between 10 mm and 40 mm (see Diagram 2 below).

As you can see from this example, these files provide:

This means you won’t need an STA rectification order to begin the work.

However, you still need to officially order the rectification design, and STA will issue a site-specific report based on the standard detail.

Having the rectification detail on file means you won’t be held up. You can get cracking on the rectification while the paperwork catches up. When the work is complete, an inspection certificate (Form 12 in Queensland) can be issued once the builder provides:

Simple.

And this new system reduces rectification design costs by approximately 35%, as well as reducing inspection costs.

For defects of greater extent or complexity, custom solutions are required. In most cases, if a defect is reported early, the solution (and certification) can be achieved quickly while the problem is still relatively minor. The table below indicates examples of defects that trigger custom solutions:

| Defect | Criteria |

|---|---|

| Frame overhang/edge beam extensions | Over 40 mm up to or over 70 mm |

| Slab edge reduction | Over 10 mm |

| Point load support on existing slab | Dead load over 15 kN |

| Plumbing pipe in slab | Cuts in slab for plumbing (standard details may apply in some cases TBC) |

| Brickwork articulation joints | Articulation joins to be added to brickwork. |

| Other miscellaneous rectifications | Standard details may apply in some cases (TBC) |

Custom solutions are also needed when multiple issues are present. Custom rectification requires a visit to the site by STA to inspect preparation of the concrete element being repaired prior to application of specified products, with reinforcement installed for inspection (when applicable).

An inspection certificate (Form 12 in Queensland) can be issued once the builder provides:

Overall, these changes streamline STA’s response in more difficult cases (custom rectification details), while also offering the convenience of standard rectification details for most other cases.

The new STA system:

But all this can’t be done without your help.

It’s OK to have a problem. To hide it doesn’t help. Take responsibility for full disclosure, including any builder rectification attempt details. The sooner STA receives all the facts, the quicker (and cheaper) the solution will come.

Trying a quick, un-engineered patch up job can cost you in the longer run when problems become apparent to inspectors or owners/developers. As you’ve seen in this blog, the process is more streamlined at the earlier, less complex end of the spectrum.

Make sure your concreters are in the loop on how defects are handled. Best practice means:

To find out more and prepare for faster, more economical rectifications, talk to the team at STA.