As a builder, you know construction can be a tough business. And with ever greater regulation and competitive cost pressures, the last thing you need is a critical delay or setback on your project.

Yet as many as one in three inspections for the foundation and slab stages will require some degree of engineering judgement — and without it, these inspections would be “failed”. This can cost you serious time and money.

To help you avoid this, we are going to take a look at the proper role of both the engineer and building certifier in the inspection process and how you can use your engineer to ensure better inspection outcomes.

To explain this further, let’s start with some basics.

Let’s first make sure we’re on the same page.

There are four mandatory prescribed “Stages” of inspection for a new home build:

For this article we’re focusing on the first two Stages: Foundation and Slab.

Each Stage has several “Aspects”.

Each Aspect requires sign off by a certifier or “competent person”, such as an engineer, surveyor, etc. These persons must be deemed competent by the certifier for the particular aspect inspected.

Competent persons cannot usually certify a Stage of building, only on certain Aspect(s) of a Stage.

Once all Aspects have been signed off by competent persons and/or building certifier, a certifier can certify an entire Stage.

Each inspection results in Inspection Certificates (a Form 16 in QLD) being issued to confirm that every Aspect within each Stage has been inspected and complies with the approved designs (plans) and relevant standards and building codes.

When all Stages have been certified, the building approval is complete.

When we talk about a Foundation and/or Slab Inspection, we’re referring to the compliance inspections that are required for construction of a building foundation and completed concrete slab.

There are several Aspect inspections that are carried out prior to the slab being poured:

| Stage | When Inspected? | Aspects | Competent person |

|---|---|---|---|

| Foundation (and Excavation) Stage | Before the footings are poured | • boundary clearances • footing excavation • reinforcement | Surveyor OR Engineer OR other person deemed competent by the certifier for each aspect |

| Slab Stage | Before the concrete is poured | • floor level check • termite treatment • reinforcement of slab • vapour barrier | Any person deemed competent by the certifier |

There are numerous elements that are inspected as part of each Aspect, with checks of up to 60 elements, including:

On a single site, more than one inspection may be required per Aspect within the Foundation and Slab Stages. This could be due to one or more of the following reasons:

When a certifier chooses to rely on a competent person, two of the Foundation Aspects have mandatory requirements for the type of person they must use:

Usually, engineers will also inspect the excavation and piers, since it’s their design. While you can book certifiers to inspect these, they can only check for compliance with the engineers’ design.

For the foundation and slab stages, the below table shows the list of Aspects that STA will typically inspect:

| Stage | Aspect | Notes | Aspects STA do not cover |

| Foundations | Excavation of foundation material | • Dimensions of excavations • Profile of soil excavated • Bearing surfaces of excavations | Residential design and siting provisions Compaction of fill material (if necessary) Cut and fill batters |

| Piers through fill | • Location of piers through compacted fill • Depth and bedding of piers through compacted fill to natural ground or in accordance with approved design requirements | ||

| Reinforcement of footing system | • Type and placement of steel reinforcing • Size and gauge of reinforcing steel • Location and dimension of laps to reinforcement steel • Type of connections to reinforcement steel | ||

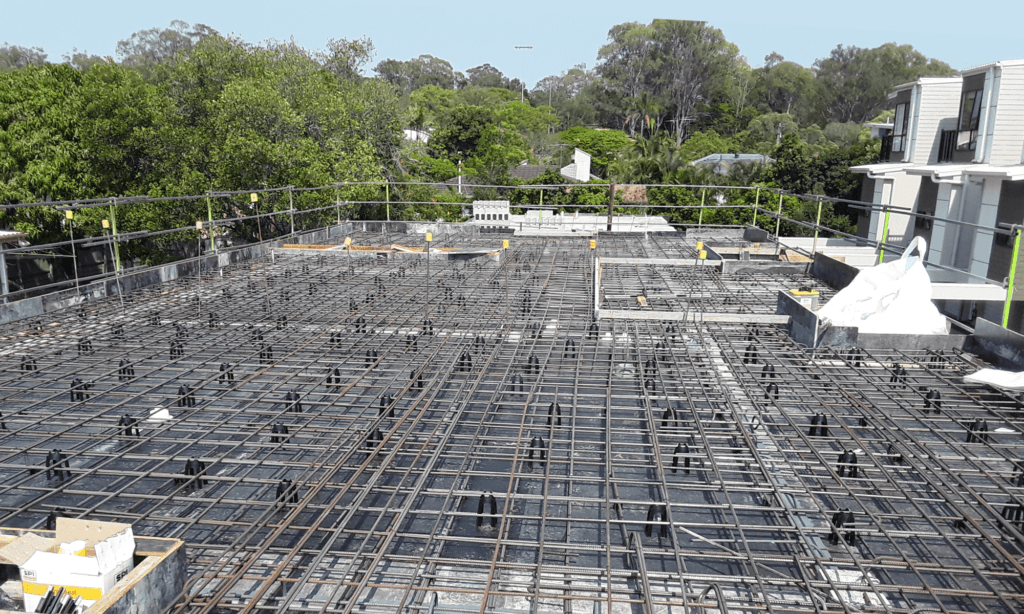

| Slab | Reinforcement of slab | • Type and placement of steel reinforcing • Size and gauge of reinforcing steel • Location and dimension of laps to reinforcement steel • Type of connections to reinforcement steel | Termite management system Floor levels |

| Vapour barrier | • Type and location of the vapour barrier • Type and location of joint overlaps to vapour barrier • Treatment to penetrations through vapour barrier | ||

There are 3 reasons you require an inspection on your foundation and slab. And all centre on ensuring you are getting what you paid for: a solid, high quality and compliant foundation.

As mentioned above, every residential foundation and slab must comply with the relevant standards and building codes. The legislation varies in each State, but essentially they all follow the National Construction Code (NCC), AS 2870 and other supporting Australian Standards referenced within these documents.

Another reason for foundation and slab inspections is peace of mind. You want to be sure that the concreter has built the foundation and slab as per the engineering design and regulatory standards.

For a builder, who ultimately takes responsibility for the work that their concreter does, an inspection gives you confidence the work has been done right and you’re getting value for money.

For a homeowner, the inspection provides greater certainty that you have quality built foundations, footings and slab that will stand the test of time.

The foundation inspection documentation would also be referred to should there ever be a problem with a foundation in the future. If engineers and certifiers are used in their proper roles, the liability for any defects or failures in the foundation is a lot clearer – more on this later.

As touched on above, you can legally book either:

A Structural Engineer, together with their trained engineering inspectors, who are deemed competent by the professional engineer and work under their direct supervision. An engineer has the professional skills to design, supervise, adjust and certify building structures. In Queensland, the engineer is registered (an RPEQ) with the Board of Professional Engineers Queensland (BPEQ). In New South Wales, no such professional registration exists, though it was recently passed into law and we can expect to see this come into effect soon.

or

A Building Certifier, who is licenced by the Queensland Building and Construction Commission (QBCC) in Queensland, or registered with Fair Trading in New South Wales, to ensure compliance with the approved building plans and appropriate building standards.

However, most certifiers and engineers prefer to work in clearly defined roles, with engineers inspecting the Aspects they have designed, and the building certifier, having oversight of all the inspections by “competent persons”, certifying the overall Stage once all Aspects have been successfully inspected.

Engineering Design (Form 15 in QLD) completed, signed and provided by the engineer as a competent person under the Building Regulation 2006. This assures that a building design or specification complies with the regulations set by relevant levels of government and/or other bodies.

Inspection Certificate (Form 16 in QLD) completed and signed by the engineer or building certifier. This assures that an Aspect of building work complies with the approved design or specification, and with relevant regulations. This is required at different stages before the various concrete pours.

You might do everything you can to keep Murphy’s Law at bay, but of all the phases in a project, the foundation and slab inspections are most susceptible to the unexpected, and there are several inspection points where problems could occur.

Things that can go wrong for inspection day include:

For many of these problems the foundation design will need to change. For others they can be fixed without design change. But no matter which, it all begs two key questions:

This will largely depend on whether you choose to book the inspection with your engineer or the building certifier.

“There’s almost always something the inspector wants adjusted/fixed, usually minor. 90% of the time, you just fix it on the day, either there and then, but certainly before the pour, after taking photos, a bit of back and forth etc. I always book a bit of time between inspection and pour where possible. Sometimes you’re fixing things with the truck waiting, but I’ve never lost a load of concrete, though a lot of blokes have.” Courtesy of one of the builders we interviewed for this article |

The latest Queensland Guidelines for inspection of class 1 and 10 buildings and structures states that the building certifier takes the “holistic view of a building rather than just consider a single aspect”. In this overseer role, certifiers prefer to appoint expert “competent persons” such as engineers to inspect specialist Aspects of a building Stage. Particularly with foundations, there are several reasons why they prefer engineers to do the inspections, rather than being called in themselves. Happily, these reasons also favour builders trying to keep their projects on track:

A certifier is a compliance inspector. For them a job either complies with the engineer’s design or it doesn’t. There’s no “in between”.

An engineer (together with an engineering inspector) is a designer, advisor, problem solver, re-designer and inspector rolled into one. Engineers also train and use engineering inspectors to perform site inspections. These inspectors are deemed competent by the engineer they are representing, who takes full professional responsibility for their work. They also have full access to the engineer – before, during and after the inspection – to ensure all questions can be answered and decisions made on site quickly.

Certifiers can only pass or fail. If any of the things listed above go wrong, a certifier must fail the inspection. The certifier will also require amended plans with a signed Engineering Design attached before inspecting again, so you need to contact the engineer about that. Once plans are reissued, you may book the certifier or engineer to attend the site again in 2–3 days’ time when available for another inspection.

Engineers understand your foundation design. Because they designed it, they have the authority to change it on site. They’re able to work with you as you lay the foundations and are better equipped to keep the build on track.

They can prevent problems and keep the job on time and budget by:

Engineer’s inspectors can attend the site and:

Ultimately, using your engineer provides flexibility to quickly adapt to what is found underground.

Building certifiers prefer engineers to do these inspections because it helps them manage their workload and stay on top of multiple projects. They know they can trust the engineer’s inspection. For you the builder, the cost to book a building certifier or an engineer for an inspection is comparable. However, if there are any issues on site, using a building certifier can cause lost time and increased expense because you may need to:

The building certifier would prefer you to get it right the first time rather than looking like the one who holds things up.

For example:

Steve the builder encounters problems on the day digging and preparing the foundation. Things are different from what was anticipated. Steve has some questions. If he calls:

The Building Certifier — the certifier cancels the inspection and says “You’ll need to contact your engineer to fix this up. You’d best book inspections with the engineer from here on.” Steve has to cancel or reschedule the concrete pump and pay his team even though there’s less to do, or send them home: “There’s nothing happening here today.” He now begins again with the engineer and doesn’t know exactly when he can reschedule the work. He loses time, money and reputation.

The Engineer — Steve describes the problems and receives advice over the phone. The engineering inspector arrives, inspects the foundation as usual, makes sure everything is compliant with what Steve was asked to do on the phone and passes the job then and there; no delays. Steve proceeds with pouring the concrete. The project stays on time and on budget.

Another key point of difference is where the responsibility lies if something goes wrong. Is the problem due to the foundation design, an issue with how it was constructed or something missed during the inspection?

If a Certifier provides the inspection, liability can be messy. It can lead to finger pointing and conjecture and ultimately be difficult to determine or prove who was actually at fault.

If an Engineer provides the inspection, they take ownership of any problem. Since the engineer provided both the foundation design and inspected that the foundation was built according to that design, it is clear that liability rests with them. If a fault was theirs, they have responsibility for any rectification work. This makes issues easier to resolve and provides peace of mind for builders, concreters and home owners alike.

Certifiers can only pass or fail. The foundation either complies with the design or it doesn’t.

Engineers can issue a “pass with conditions”, meaning some rectifying action is to be done and confirmed before the concrete pour. With as many as 1 in 3 foundation inspections not meeting the pass/fail criteria of a building certifier, and with both being comparable in price, you can’t afford not to engage an engineer for this aspect, preferably the one who designed it in the first place.

At STA Consulting Engineers, we’ve engineered the process to be as smooth as possible, integrating our own Inspection App with a traffic light system for inspection results:

We advise your traffic light status after:

Our Inspection Process is simple and ensures the builder and concreter are well informed throughout:

This is all part of STA’s easy 5-step foundation inspection process, so you can go from booking your service through to receipt of certification documentation in just five easy steps, while keeping all the right people informed along the way.

To get on the right track with your foundation inspection, call us to book or ask questions on (07) 3071 7444 (QLD) or (02) 4032 6450 (NSW), or request a quote online.

Or to find out more about all our Inspection Services, head over to our Service page.